Human-Machine Interfaces (HMIs)-GOT FA Application Package iQ Monozukuri

Easily operate at the production site!

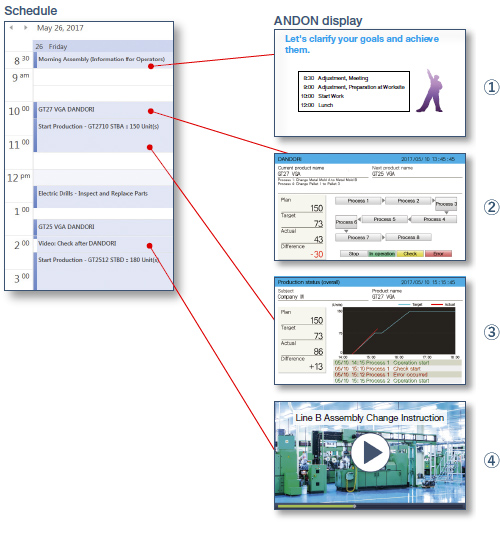

Using the Contents Publisher, it is possible to set the contents (such as production plan, uptime status, and messages) to be displayed on the ANDON monitor easily.

Setting schedule Contents Publisher

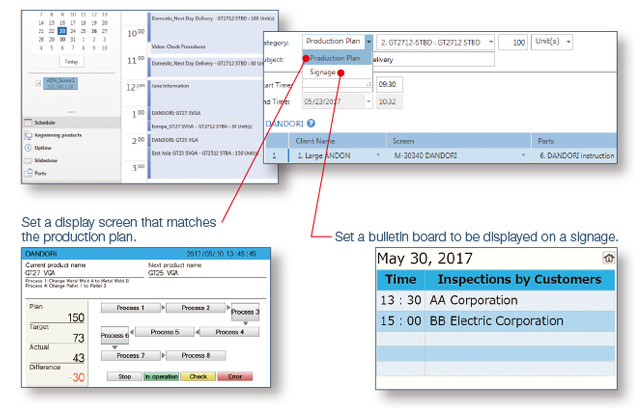

You can easily set up the DANDORI instruction screen according to the production plan and the screen you want to display on the signage screen (bulletin board, etc.).

Image of setting schedule and ANDON display Contents Publisher

According to the schedule settings, the ANDON display is switched in order.

①Signage screen

Displays a bulletin board for messages and operating instruction text.

②DANDORI screen

Displays the product name and details of DANDORI.

③Production status screen

Displays the difference between the target quantity and production result in a graph (progress chart).

Also, events and alarm occurrence status are listed.

④Slideshow

Displays multiple screens such as a product image and operation procedure video in turn in certain intervals.

How to set Contents Publisher Contents Publisher

The ANDON screen display can be set and changed using easy settings of Contents Publisher even without programming knowledge for configuring the ANDON system.

Click here for the Contents Publisher Quick Start Guide movie.

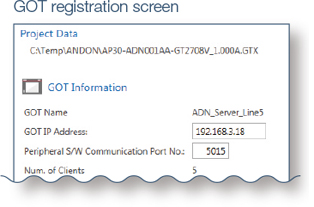

1)Registering GOT

Register the information of GOT, which is the server that manages ANDON.

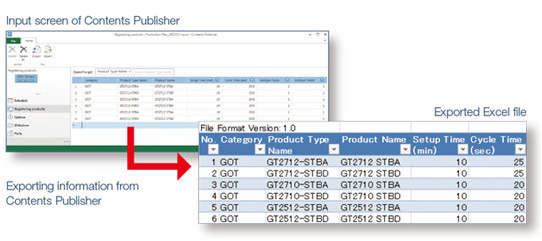

2)Registering product information

Register the information of a product to be produced.

In addition to directly inputting information to Contents Publisher, you can also export information to an Excel file (.xlsx), edit product information collectively, and then import the data.

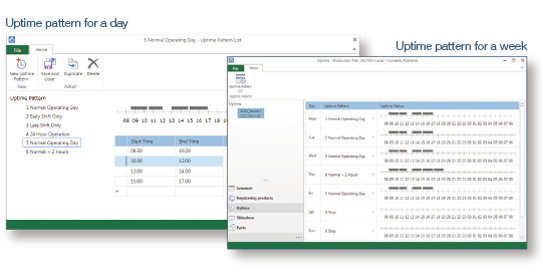

3)Setting uptime

Set the uptime pattern (working hours, rest period and others) of the production site for a day and for a week.

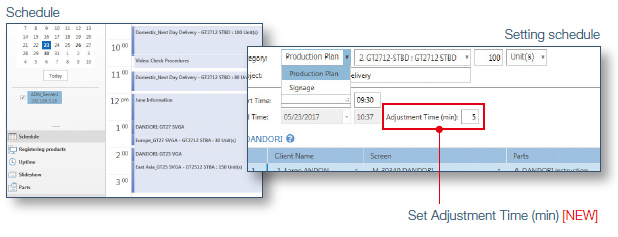

4)Setting schedule

Set the schedule based on the production plan.

The adjustment time can be set because the time required for adjustment work is different between skilled and unskilled workers.

5)Transferring schedule

Transfer the set schedule to the GOT and realize ANDON display.

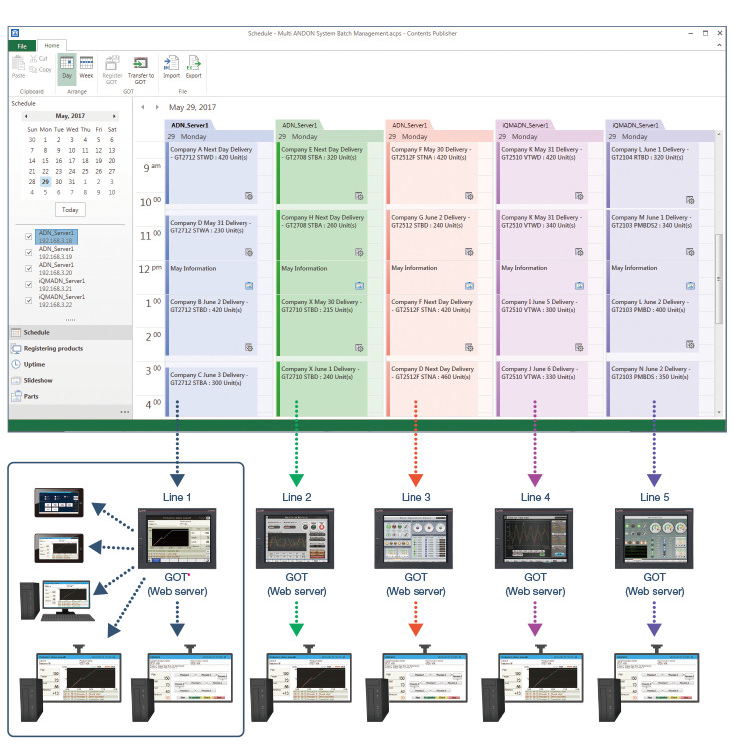

Manage multiple ANDON systems collectively! Contents Publisher

By registering multiple ANDON GOTs, screens displayed on ANDON can be managed collectively. (Up to five GOTs)

Contents Publisher manages multiple ANDON GOTs that are installed in the same equipment or the same production line so that it is

possible to collectively reflect changes of information about production plans and bulletin boards.

- *Up to five clients (display terminals) can display ANDON data through one GOT (Web server).

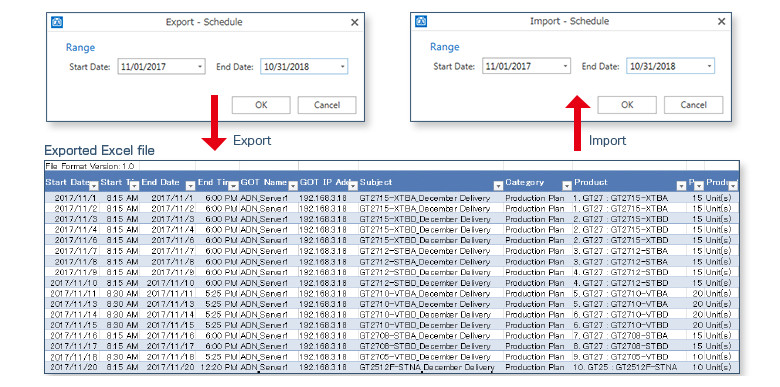

Export/import schedule Contents Publisher

When you want to change the schedule (production plan or signage screens) collectively, you can export the schedule and collectively change it in Excel.

The target range can be specified by date so that the schedule of an arbitrary period (maximum 1 year) can be changed at a time. NEW

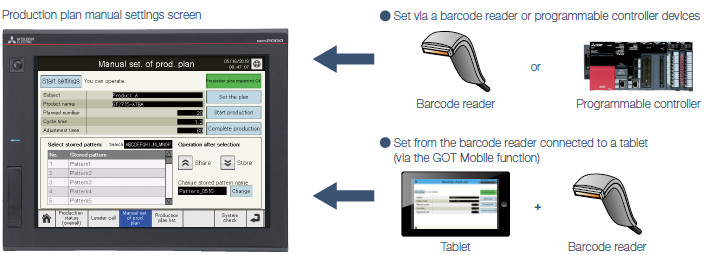

Enter the production plan from the on-site GOT NEW Template screen

On the production plan manual settings screen, the production plan can be entered from the on-site GOT. It can be set per product via a barcode reader or programmable controller devices. Frequently used patterns can also be registered.

- *In addition to the above manual setting methods, the production plan can also be set or changed using Contents Publisher or ANDON DB (database). Note that these methods cannot be used with manual setting methods.

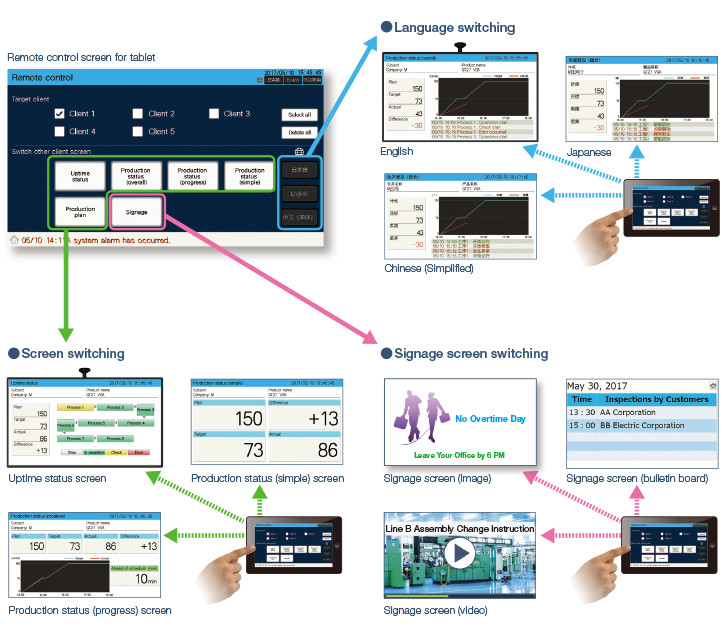

Switch ANDON screens by remote control operation from a tablet! Template screen

The display screen of the specified ANDON monitor and the display language can be switched by using remote control operation.

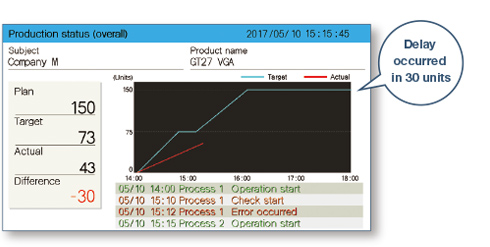

Display production results in numerical values and in a graph (progress chart) Template screen

The production status (overall) screen displays the production planned value, target value, actual value, and the difference between the target and actual values numerically. Also, delays can be detected timely because the difference between the target value and production results can be checked graphically on a progress chart.

Visualizing problems

Production delays against the target and alarm occurrence status can be checked on the progress chart.

Planning measures

This screen is helpful to plan measures such as changing the production plan.

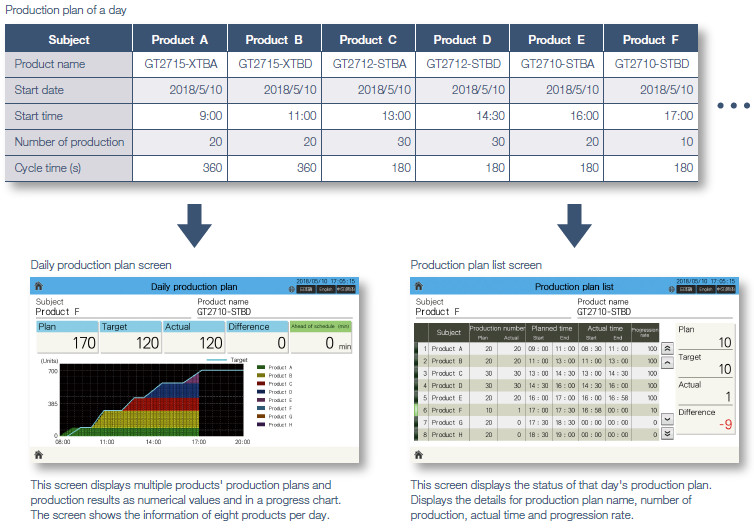

Display the production plans and results of multiple products on one screen NEW Template screen

If multiple products are manufactured on one day, the production plans and results of the day can be displayed as one progress chart. On the production plan list screen, the production plans and results of a day can be confirmed on one screen.