SolutionsTotal Maintenance

In today’s dramatically changing business environment, the impact of sudden equipment downtime on corporate profits is enormous, and an increasing number of businesses are implementing planned equipment maintenance with the aim of achieving non-stop factories.

Meanwhile, the manufacturing industry faces another major issue of passing down the expertise of highly experienced employees.

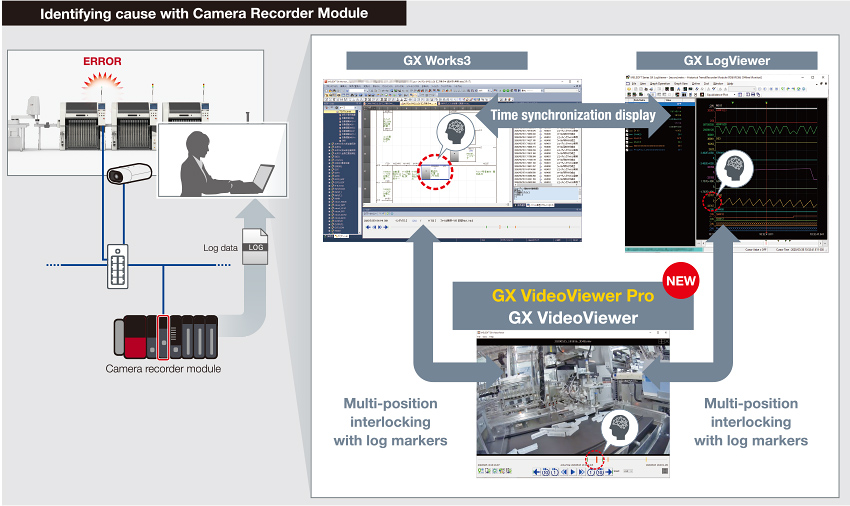

Case09Identifying the cause of equipment errors

Corrective

Maintenance

Equipment level

Identifying the cause of an error by visually checking equipment is not possible as it looks in normal condition.

The video recorded with the camera runs too fast, making identifying the error cause difficult.

Investigate equipment error causes with a system recorder

The system recorder*1 performs system-wide recording of equipment operation data and camera images in the event of an abnormality. Analysis is made easy by displaying waveform data, programs, and video data on the same timeline. Also, GX VideoViewer Pro analyzes the video footages and indicates areas different from normal operation (differences), and milestone points (log markers) are added automatically in the meantime.

*1 System recorder: corrective maintenance solution that greatly reduces downtime through system-wide recording in the event of an abnormality and simplified analysis.

Any causes of failures that were difficult to find before can be identified, and errors that are likely to cause failures are avoided in advance.