SolutionsTotal Maintenance

In today’s dramatically changing business environment, the impact of sudden equipment downtime on corporate profits is enormous, and an increasing number of businesses are implementing planned equipment maintenance with the aim of achieving non-stop factories.

Meanwhile, the manufacturing industry faces another major issue of passing down the expertise of highly experienced employees.

Case10Responding to equipment problems without going to the shop floor

Corrective

Maintenance

Equipment level

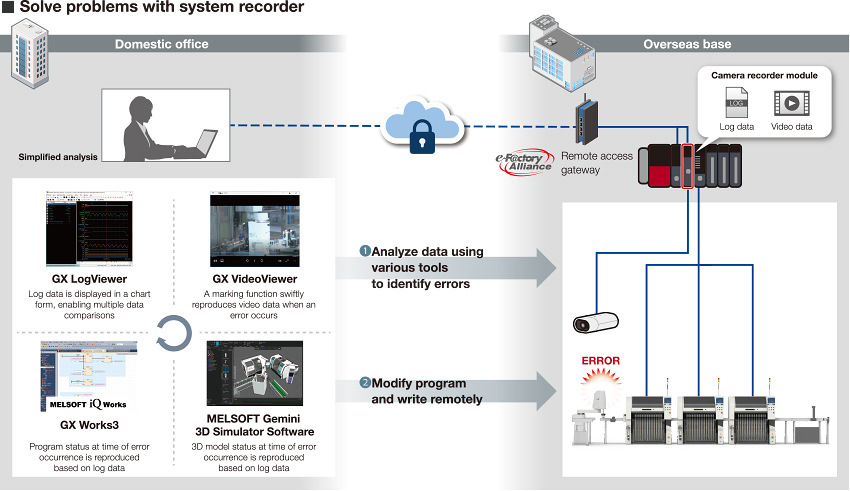

When an abnormality occurs on the shop floor at another facility (overseas, etc.), it is difficult to accurately understand the cause by phone or e-mail alone.

In order to investigate the cause and recover the shop floor to normal operations, it is necessary to go to the site where the problem is occurring, and this form of response is time-consuming and costly.

Confirm the status and error details of an equipment at a remote location via video images and 3D simulator, and thus the cause can be found quickly.

The system recorder*1 performs system-wide recording of equipment operation data and camera images in the event of an abnormality. Waveform data, programs, and video data of the shop floor are obtained at remote locations, and operations can be confirmed through these data by linking 3D simulator and other tools. Remote environments are easily and securely built using Ewon/Secomea remote solutions.

*1 System recorder: Corrective maintenance solution that greatly reduces downtime through system-wide recording in the event of an abnormality and simplified analysis.

Labor hours and costs are significantly reduced by identifying error causes at an early stage from a remote location.

In addition to the video data, the 3D simulator is available to check operations and makes it possible to confirm operations of equipment blind spots or the inside of an equipment that cannot be seen physically.